The technology will allow customers to have custom sill plates, puddle lights and dashboard trim

Mini is turning to 3D printing technology to offer its customers a wider range of personalisation options.

From 2018 onwards new and existing Mini owners will be able to design their own exterior and interior trim components via a dedicated online configurator. "Individualisation has always been a big topic with Mini," said Thomas Schmitz, product manager of Mini Yours Customised. "Now we want to take individualisation to the next level."

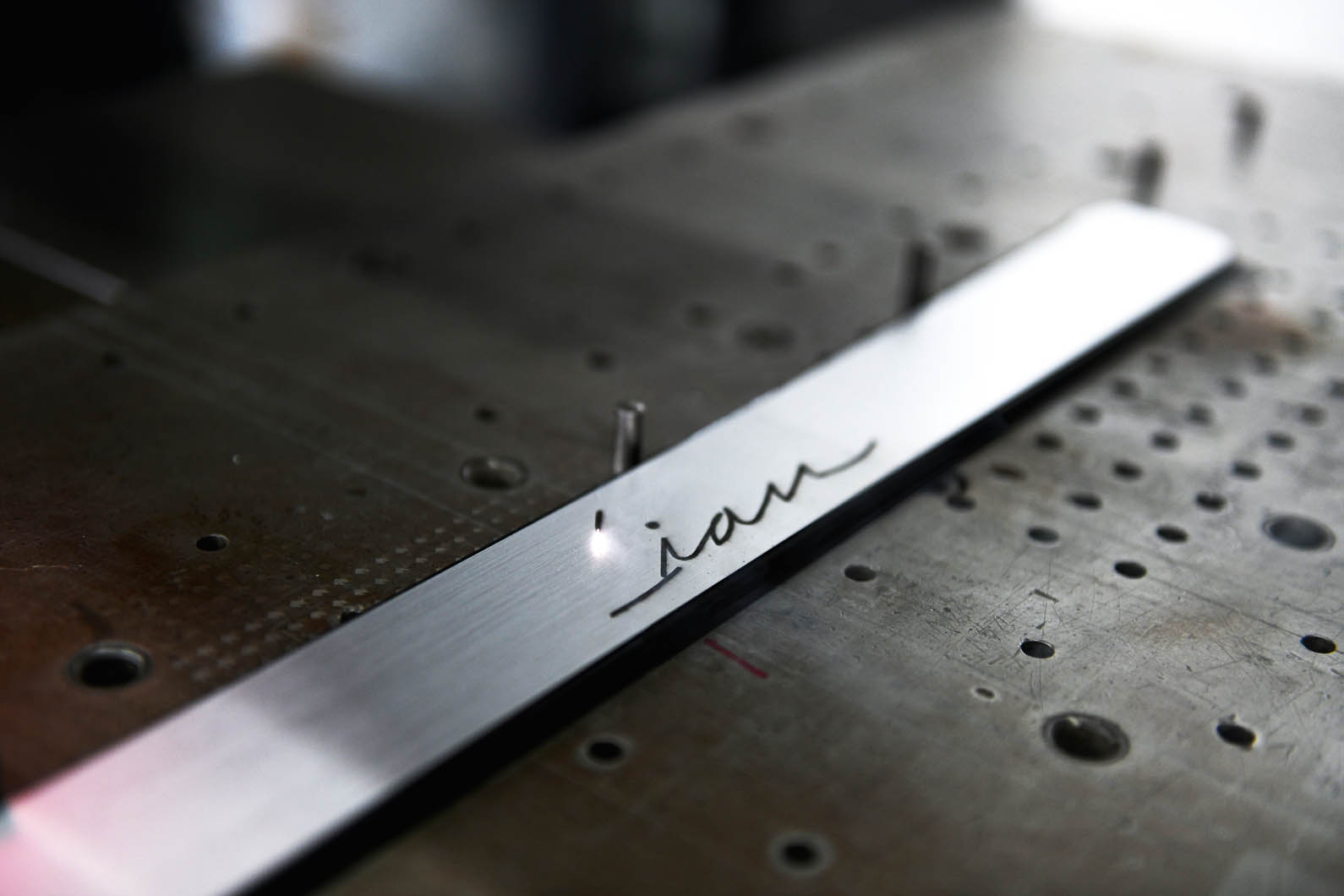

The upgrade package includes 3D-printed side indicator inlays and dashboard trim, as well as personalised sill plates and LED puddle lights. The indicator inlays and dashboard facia come in one of five colours and can display text, simple images and textured patterns, or one of a small selection of cityscapes. Using a laser etching technique, meanwhile, the illuminated sill plates can present text in the owner's handwriting, basic graphics and even star constellations. Additionally, when the doors are opened, the puddle lights project personalised text onto the ground.

The components, which are designed to be fitted at home, will be manufactured in Munich, with Mini anticipating a four-week lead time once the designs have been submitted. Each component is subject to the same BMW Group crash and durability tests as any other item of trim.

Given the cost and complexity of 3D printing, Mini teamed up with computing giant Hewlett Packard to refine the process. UK pricing is yet to be confirmed but European customers will pay €40 (around £35) for a pair of personalised puddle lights and €140 (£124) for the dashboard facia.

Related stories:

Mini GP review

Mini Cooper S Works review

Mini Countryman review